- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

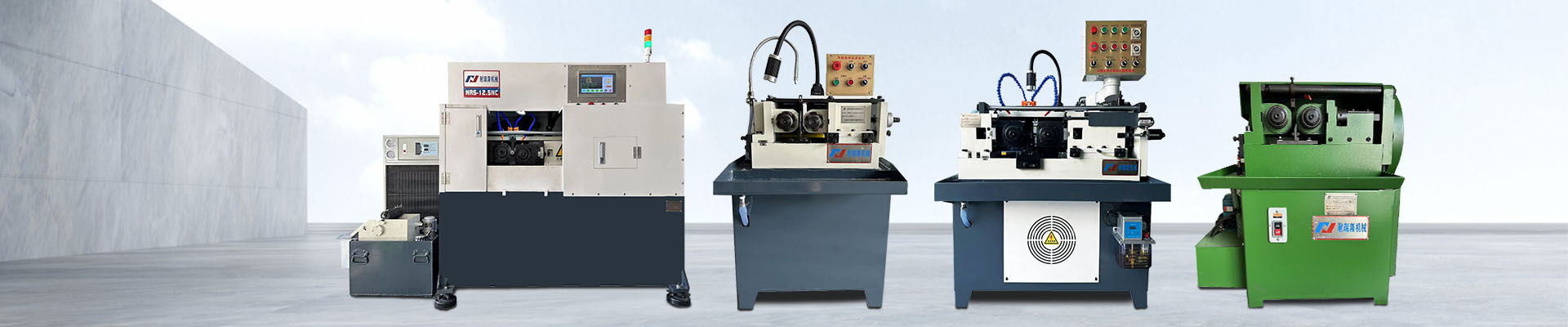

3 Roll Thread Rolling Machine For Tube

3 Roll Thread Rolling Machine For Tube can be convenient to process all kinds of tubular threads, but also suitable for all kinds of knurling, mesh, straight lines and other processing; Using equal triangle support operation, to ensure roundness, perpendicularity, easy to pass through the gauge and stop gauge; Using hydraulic (hydraulic) drive, easy operation, stable frame, durable, widely used in tubing joint, steam engine car bicycle parts and air conditioning tube evaporator, various fasteners, condenser copper pipe and other workpiece wire rolling processing.

Model:NRS-35A

Send Inquiry

You can rest assured to buy NERES 3 Roll Thread Rolling Machine For Tube from our factory and we will offer you the best after-sale service and timely delivery. We have the distinct advantage because the success of our company is directly related to each and every individual. We take pride in all we do, and we take pride in a job well done. 3 Roll Thread Rolling Machine For Tube can be convenient to process all kinds of tubular threads, but also suitable for all kinds of knurling, mesh, straight lines and other processing; Using equal triangle support operation, to ensure roundness, perpendicularity, easy to pass through the gauge and stop gauge; Using hydraulic (hydraulic) drive, easy operation, stable frame, durable, widely used in tubing joint, steam engine car bicycle parts and air conditioning tube evaporator, various fasteners, condenser copper pipe and other workpiece wire rolling processing.

1. Specially designed for tubular thread thin wall pipe 1.5mm above, can be rolled thread, mesh, straight grain, etc.

2. Such as triangular support, to ensure the circularity, concentricity and perpendicularity.

3. Driven by oil pressure, easy operation, fast and slow function, stable and efficient.

4. Compact structure, cast steel body strong rigidity.

5. Simple structure, built-in tank, less space, easy maintenance.

6. Automatic feeding device can be installed to realize automatic production.

7. Frequency conversion power, spindle speed arbitrary adjustment.

8. PLC programming control, man-machine interface control freely.

9. Fully functional, automatic, semi-automatic, manual, switch freely.

10. When automatic production is not required, the feeding device can be moved away, and manual operation can be performed by switching to semi-automatic.

|

Rolling Dia. |

12~35mm |

|

Pith |

0.5~2.5 mm |

|

Rolling length |

10~50mm |

|

Taper of thread |

1:16 |

|

Ht. From table surface to center of rolling |

285mm |

|

Rolling spindle DIA. |

35mm |

|

Rolling dies KEY WAY |

10 mm |

|

Rolling dies DIA. |

Ø90 mm |

|

Rolling dies thickness |

30~50mm |

|

Max. pressure per unit area of the cylinder |

120 kilograms per square centimeter |

|

MAX. Rolling pressure |

4800KG |

|

Variable pump |

20 liters per minute |

|

Spindle speed |

400RPM |

|

Main power motor |

3KW-4HP |

|

Hydraulic motor |

1.5KW-4HP |

|

Cooling water pump |

40 watts |

|

Operation required space |

1100mmx850mmx1400mm |

|

Net weight |

700 kgs |