- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

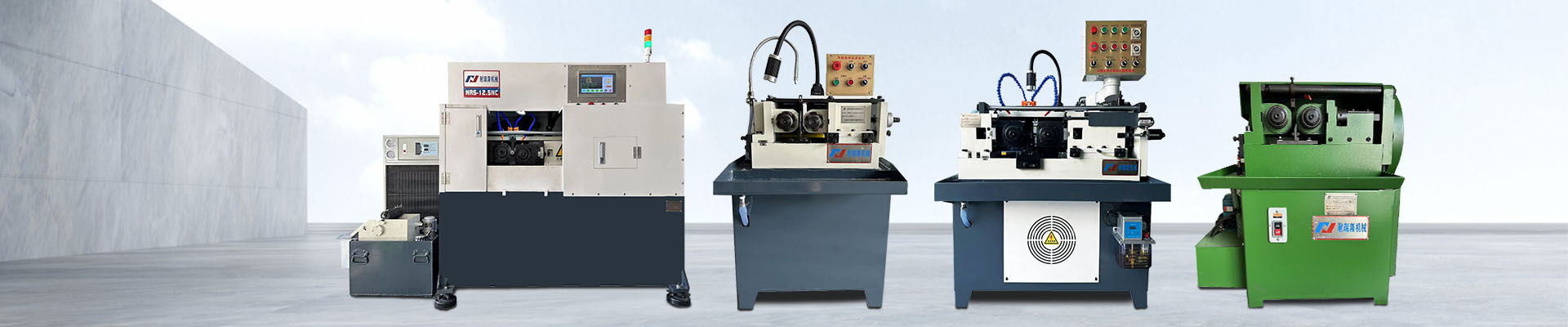

Automatic CNC Thread Rolling Machine

Automatic CNC Thread Rolling Machine has the characteristics of higher rolling accuracy and digitization, and easier automation.

Model:NRS-25NC

Send Inquiry

Automatic CNC Thread Rolling Machine has the characteristics of higher rolling accuracy and digitization, and easier automation.

Dongguan Neres Hardware Machinery co., LTD. Is a Thread Rolling Manufacturer in China, Automatic CNC Thread Rolling Machine is my factory use of advanced digital control technology independent research and development of high-performance roll forming machine. It is mainly used for cold forming of small modulus involute spline and high precision external thread. It can also be used for cold rolling forming of other high precision conodont. Has the following advantages:

●Touch screen operation panel, more precision control;

●On the basis of high rigid bed, the comprehensive design of various rolling fixture required;

●Three-axis servo operation, improve the accuracy and mold life;

●This Automatic CNC Thread Rolling Machine is Simple operation, the left and right spindle can be adjusted by data input between the roller tooth distance and tooth position, the size of the center distance of the left and right spindle can be adjusted by input data;

●Can be high rolling, the left and right spindle through their own independent servo motor drive, through synchronous control can eliminate tooth bias to achieve high precision rolling;

●Non-hydraulic feed ball screw, reduce the influence of hydraulic temperature change on machining accuracy;

●With radial rolling, axial rolling, rerolling, reciprocating rolling 4 processing methods, can be the same workpiece for multi-station rolling in turn;

●This Automatic CNC Thread Rolling Machine is Equipped with special parts, can realize spline shaft, vortex shaft, ordinary thread, straight grain, mesh and other parts for precision rolling;

The Videos:

We have two typs of CNC thread rolling machine: NRS-25NC and NRS-15NC.

The following is CNC thread rolling machine NRS-25 specifications:

|

Technical Specifications |

NRS-25NC |

|

|

Product Name |

Automatic CNC Thread Rolling Machine |

|

|

Range of thread |

Plunge rolling MAX. diameter |

80mm |

|

Thru feed rolling MAX. diameter |

45mm |

|

|

Rang of length(in-feed) |

120mm |

|

|

Rang of length(thru-feed) |

3000mm |

|

|

Spindle speed |

1~60rpm/min CVT |

|

|

Right spindle feed speed |

MAX.600mm/min |

|

|

The distance between the spindles |

180mm~280mm |

|

|

Spindle trave |

100mm |

|

|

Spindle rotation Angle |

±7.5° |

|

|

Height from datum level to center of spindle |

180mm |

|

|

Ball screw lubrication |

Automatic forced lubrication |

|

|

Lubrication of right spindle guide surface |

||

|

Thread rolling dies |

MAX. diameter |

220mm |

|

Bore diameter |

75mm |

|

|

Width range |

150mm |

|

|

Key way |

|

|

|

Motor power for spindle drive |

servomotor2×5.5kw |

|

|

Collant power |

0.09kw |

|

|

Max rolling pressure |

250KN |

|

|

Height from floor to spindle center |

950mm |

|

|

Operation required space |

2100mm*1600mm*2100mm |

|

|

Net weight |

3200kgs |

|

|

Number of control axes |

3 axes |

|

|

Right spindle mobile servo motor |

5.5kw |

|

|

Min.instruction unit |

Straight axi |

0.001mm |

|

Rotation axi |

0.001° |

|