- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

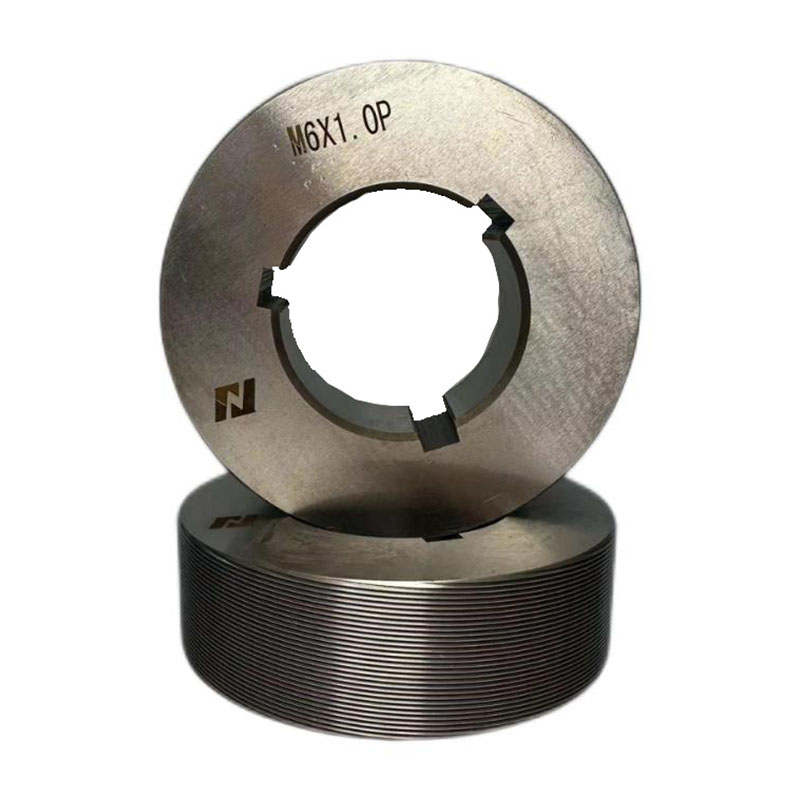

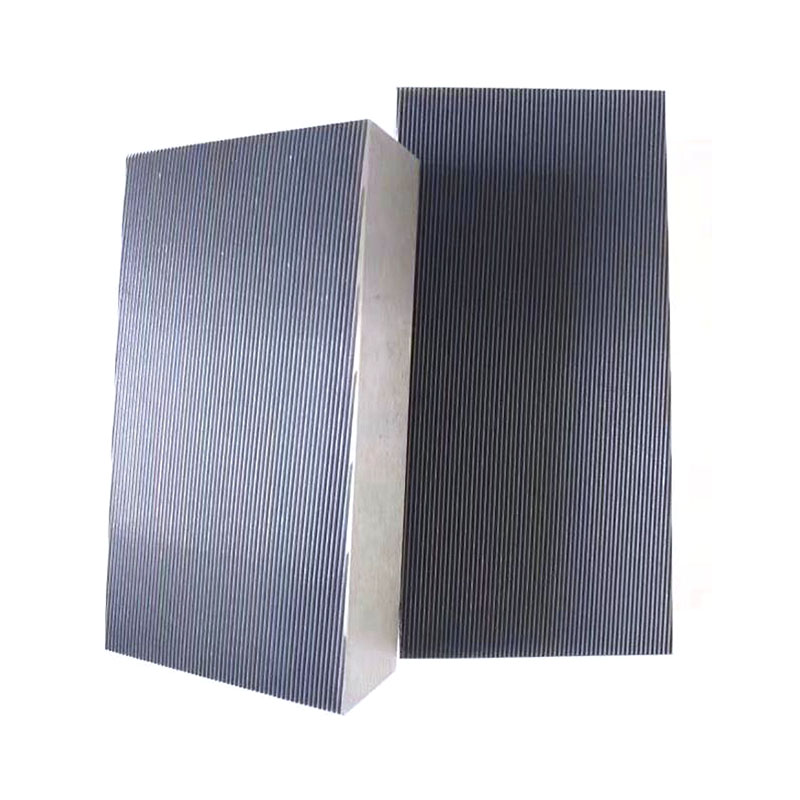

Flat Diamond Knurling Dies

As the professional manufacture, we would like to provide you NERES Flat Diamond Knurling Dies. And we will offer you the best after-sale service and timely delivery. The non-slip and beautiful straight line or cross pattern printed on the hand tools are pressed by the roller wheel. The flower wheel is used after milling gear machine and milling. Although the surface accuracy is not accurate after grinding, the concentricity and straightness of the flower wheel also make the workpiece achieve the effect of anti-skid and beauty.

Send Inquiry

Flat Diamond Knurling Dies(Knurling rolling dies)

As the professional manufacture, we would like to provide you NERES Flat Diamond Knurling Dies. And we will offer you the best after-sale service and timely delivery. The non-slip and beautiful straight line or cross pattern printed on the hand tools are pressed by the roller wheel. The flower wheel is used after milling gear machine and milling. Although the surface accuracy is not accurate after grinding, the concentricity and straightness of the flower wheel also make the workpiece achieve the effect of anti-skid and beauty.

The Neres Flat Diamond Knurling Dies process for tumbled work responds to the growing demand for tumbled forms used in applications requiring fixture, pressing, or clad molding features. Ratchet handles, door handles, electromechanical pivot, and grip pins are common types of roller parts. Neres Tumb form is a special pressure fit tumb configuration, which can increase the concentricity and grip force of the pressure fit, while reducing the pressure. Functionally, burflowers differ from splines and serrations because they generally do not have precision sliding fit with mating parts that require high-precision tooth spacing characteristics. Using the Neres feed, single turn, or through-feed roll process, burbs can be rolled on various components to achieve precise tolerance levels.