- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

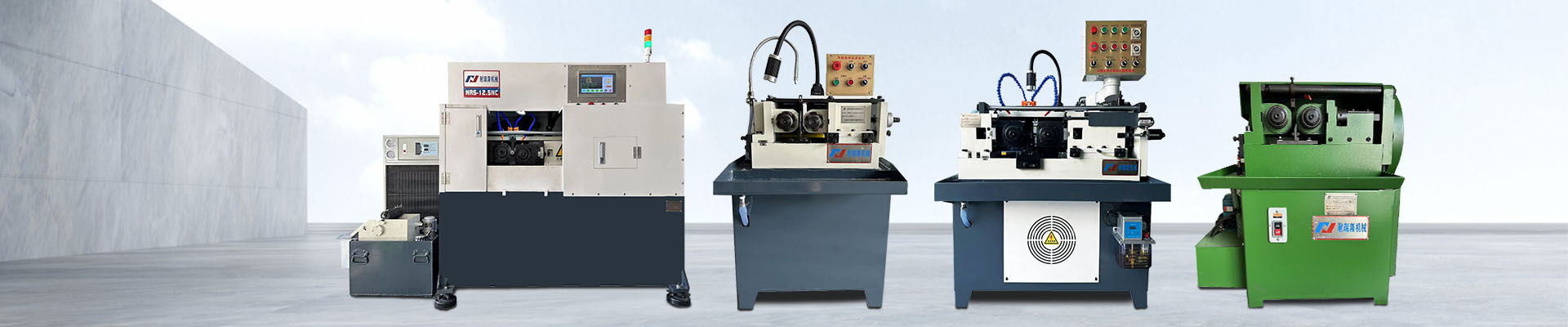

Hydraulic High Precision Thread Rolling Machine

As the professional manufacture, we would like to provide you NERES Hydraulic High Precision Thread Rolling Machine. High precision and solid resistance. The operation is very simple and versatile: the two rollers in the roller machine roll the screws, but by cooling casting process instead of cutting form the metal structure, the benefits of this process not only can more quickly and mass production of screws, and than the rolling screws produced by cutting method has greater elongation, shear force and practicability. So military and aerospace for screw tensile strength, shear strength and fatigue strength demanding demand must use this method.

Send Inquiry

As the professional manufacture, we would like to provide you NERES Hydraulic High Precision Thread Rolling Machine. the implementation of a full range of quality management strategy to ensure product quality, the whole process of quality testing and tracking, do not let go of any small details, so that your choice of reassurance more at ease.

Hydraulic High Precision Thread Rolling Machine

1. Strong structure: the left frame and the right frame form an L-shaped assembly structure with strong resistance and good rigidity

2 precision stability: double oil pressure system, PLC program control, processing quality average more stable

3 oil pressure channel strong: piston type and blade type

4. The gear box is installed with the function of adjusting tooth backlash, the rolling work size conversion, and the function of debugging spindle tolerance

5. Long life: the main parts of the machine: universal joint, frequency converter, hydraulic system, micro dynamic switch, long working life, processing high precision products more stable

Hydraulic High Precision Thread Rolling Machine: Hydraulic high precision thread rolling machine:

High precision and solid resistance. The operation is very simple and versatile: the two rollers in the roller machine roll the screws, but by cooling casting process instead of cutting form the metal structure, the benefits of this process not only can more quickly and mass production of screws, and than the rolling screws produced by cutting method has greater elongation, shear force and practicability. So military and aerospace for screw tensile strength, shear strength and fatigue strength demanding demand must use this method.

This machine uses gear reduction ratio to advance and retreat CAM to roll screws, easy to operate and high precision hobbing. The skateboard seat by high wave cycle treatment, after grinding, must use phosphor bronze oblique slightly adjusted, increase the progress, CAM to smooth climbing. Increase rolling pressure and stability of the slide. And the addition of an oil feeding system to prolong the life of the slide.

Hydraulic High Precision Thread Rolling Machine: Hydraulic high precision thread rolling machine:

1. The sliding plate and bilateral T-shaped track glide, and slightly adjusted with oblique type, in the heavy pressure rolling type, the sliding plate is stable and never rises, the sliding seat is not easy to wear, the T-shaped track after heat treatment grinding, the T-shaped rail oil feeding system (timing) changes the advantages of extending the life of the sliding rail.

2. the slide stroke and speed can be adjusted at will, rolling pressure can be selected from the oil pressure valve, from 0.5 tons to 120 tons, sealing tube or square teeth and steam engine gear shaft rolling is more appropriate.

3. There are 4 kinds of rotating speed of the roller shaft in the second order, and the direct change speed (20-170P.M) is sealed by the thickness of the teeth or the size of the circular circle of the wheel. The rolling speed can be matched appropriately, which makes the quality more excellent, and the life of the roller increases, and the output increases.

4. The rolling TIME can be automatically controlled by time, which can be from 0.1 seconds to no reality (i.e., the maximum rolling time), or stop immediately after interruption. The quality quality is greatly affected, because the rolling time of fine thread is short and the rolling time of coarse rib is long, so the rolling teeth of the matching are more economical!

5. the whole structure is strong, and oil rolling, mechanism and cast steel integration, and crystal 24 hours modulation tempering treatment.

6. can be installed microcomputer set inch switch, and foot emergency knife switch.

7. the body of the body is all made of iron plate welding molding, and after modulation and tempering treatment, 8, the oil pressure box and the body as a whole, reduce the floor area.

9. The circulating oil feeding system of the gearbox can reduce the high temperature caused by the ohm rotating friction, so as to prolong the ohm service life.

Hydraulic High Precision Thread Rolling Machine: Hydraulic high precision thread rolling machine:

1. Center height is accurate.

2, simple mechanism, wide use.

3, suitable for mass production, improve work efficiency.

Use:

1, suitable for pipe street, tooth rolling processing.

2, suitable for pipe tooth hobbing knurling processing.

3, suitable for: art gallery, classical ceiling fans, bicycle drums, and all kinds of pipes.

Hydraulic High Precision Thread Rolling Machine

This machine uses eccentric rolling small screws, such as needle screws, electronic screws, straight/oblique pattern and other high quality parts.

The advantages of tooth rolling machine: 1. High precision 2. Solid and beautiful structure 3. Widely used

Features: fast and efficient; Eccentric feed cold extrusion of small hardware shaft parts processing equipment.

Wire rolling machine appearance design is strong and beautiful, simple and convenient operation, using two axes eccentric feed, greatly improve the product accuracy. Products are economical and affordable, divided into fixed models and rolling models, for customers to choose the right type of equipment according to product requirements. Mainly for automatic car, CNC lathe, ordinary instrument lathe production of small hardware shaft parts, equipment processing diameter range is generally 1mm - 20mm. For example: instrument, watch, toy motor (miniature motor shaft), computer screws, electrical plastic hardware shaft and knurled accessories, small cylinder hydraulic cylinder shaft, confidential screws and bolts, miniature drive shaft rolling straight products

|

SPECIFCATIONS |

ITEM |

NRS-12.5 |

|

Rang of throad |

Max. diameter |

Ø30mm |

|

Min.diameter |

Ø4MM |

|

|

Pitch |

0.6-3.0MM |

|

|

Rang of 1ength(ub-feed) |

100LMM |

|

|

Rang of length(thr-feed) |

Infinite 1 |

|

|

Speed range |

10-60PRM |

15-50PRM |

|

Rolling Dies |

Max.Diameter |

178MM |

|

Bore.Diameter |

Ø 54MM |

|

|

Width.Range |

100MM |

|

|

Key way |

12*5mm |

|

|

aulic power |

Max.diameter |

240mm |

|

Min.diameter |

120mm |

|

|

Max.rolling pressure |

150KN |

|

|

Main power |

2.2KW |

|

|

Hydraulic power |

4KW |

|

|

c11lant power |

|

|

|

Height from ground to roller center mm |

1050mm |

|

|

Floor space required |

1345*1250Wmm |

|

|

Over height |

1515mm |

|

|

Weight |

Net weight |

1700kgs |

|

Gross weight |

1850kgs |

|