- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

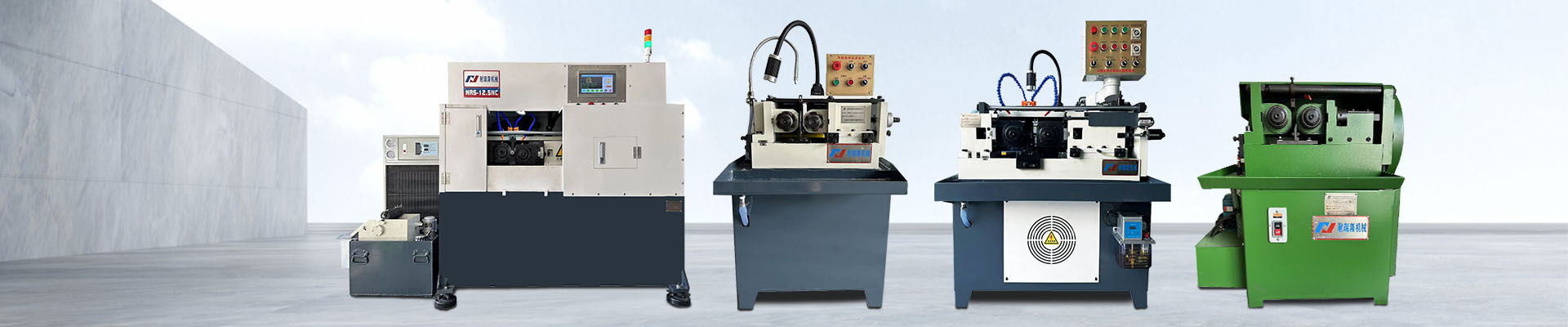

Hydraulic Thru Feed Type Thread Rolling Machine

You can rest assured to buy NERES Hydraulic Thru Feed Type Thread Rolling Machine from our factory, Hydraulic indeed Thru Feed Type Thread Rolling Machine NRS-18T precision stability: the machine adopts the oil pressure system frequency conversion mechanism, PLC program control pressure and automatic impact pressure system combination, stable oil temperature in rolling.

Model:NRS-18T

Send Inquiry

You can rest assured to buy NERES Hydraulic Thru Feed Type Thread Rolling Machine from our factory. We will always adhere to the principle of "quality first, client first," and we cordially invite customers to visit us for consultation. Hydraulic indeed Thru Feed Type Thread Rolling Machine NRS-18T precision stability: the machine adopts the oil pressure system frequency conversion mechanism, PLC program control pressure and automatic impact pressure system combination, stable oil temperature in rolling.

Hydraulic indeed Thru Feed Type Thread Rolling Machine NRS-18T Features:

1, Hydraulic Thru Feed Type Thread Rolling Machine is strong structure: this series of models left frame and right frame (into L shape) two point assembly structure, strong resistance, good rigidity. Especially the skateboard after special shovel flower processing, in the long-term pressure processing skateboard is more stable and not easy to wear.

2, accuracy stability: the machine adopts hydraulic system frequency conversion mechanism, PLC program control pressure and automatic impact pressure system, in rolling oil temperature level is stable, does not affect output, does not produce oil temperature difference makes the average quality of the workpiece more stable.

3, oil pressure channel strong: general oil pressure pump is divided into two kinds:

A. Piston type, maximum output pressure KGM210KG

B. Blade type, maximum output pressure KGM120KG

This series of models use piston type hydraulic pump, the output pressure is large, so that the oil pressure is more stable.

Cylinder diameter of NRS series models is:

|

NRS-10CM |

NRS-13CM |

NRS-15CM |

NRS-18CM |

NRS-25CM |

|

φ100CM |

φ125CM |

φ160CM |

φ180CM |

φ250CM |

|

60KG |

80KG |

100KG |

130KG |

180KG |

4, the gear box is equipped with the function of adjusting tooth backlash, so that after the outer diameter of the rolling workpiece is converted and the processing time is long, it has the function of debugging spindle tolerance.

5, long life: machine structure performance balance is good, strong rigidity, stable oil pressure, and the main parts such as: universal joint, frequency converter, oil pressure system, micro dynamic response

The switches are imported and assembled from the original equipment made by the daily system, which makes the working life long, low loss of the cone and more stable processing of high precision products.

The structure of this series of models is comparable to Europe, Japan and other models.

|

Name Specification |

ITEM |

NRS-18T |

|

Range of thread |

Max.diameter |

Ф60 mm |

|

Min.diameter |

Ф6mm |

|

|

Pitch |

0.6-4mm |

|

|

Range of length(in feed) |

5-150mm |

|

|

Range of length(thru feed) |

Free |

|

|

Speed Range |

|

0-50 R.P.M |

|

Thread rolling Dies |

Max.diameter |

Ф178mm |

|

Bore diameter |

ф54mm (Changeable Axis) |

|

|

Width range |

50-150mm |

|

|

Key way |

12mm |

|

|

Dies spindle |

Max.diameter |

190mm |

|

Min.diameter |

130mm |

|

|

Maximum rolling pressure |

Max rolling pressure |

18Tons |

|

Roller drive horsepower |

Main power |

10HP(7.5kw) |

|

Hydraulic system horsepower |

Hydraulic power |

3HP(2.2kw) |

|

Cooling pump horsepower |

Coolant power |

1/4HP(0.18kw) |

|

Height from ground to roller center |

Height from Floor to Spindle center |

1000mm |

|

cover an area |

Floor Speace Required(LxWxH)m/m |

1660x1550x1700mm |

|

Weight |

Net weight |

2100kgs |

|

Gross weight |

2500kgs |