- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

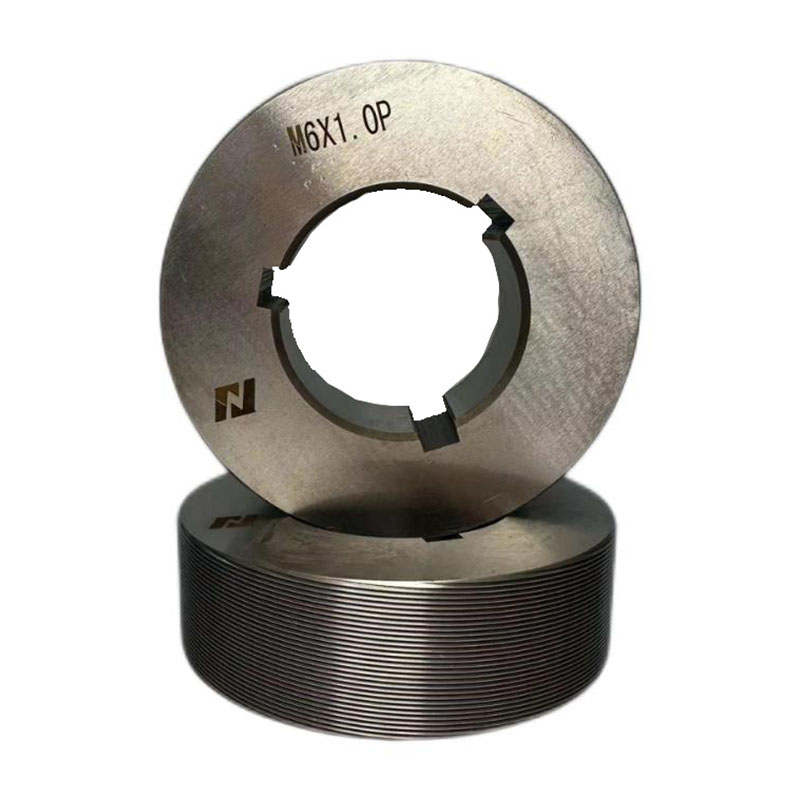

MJ Aerospace Thread

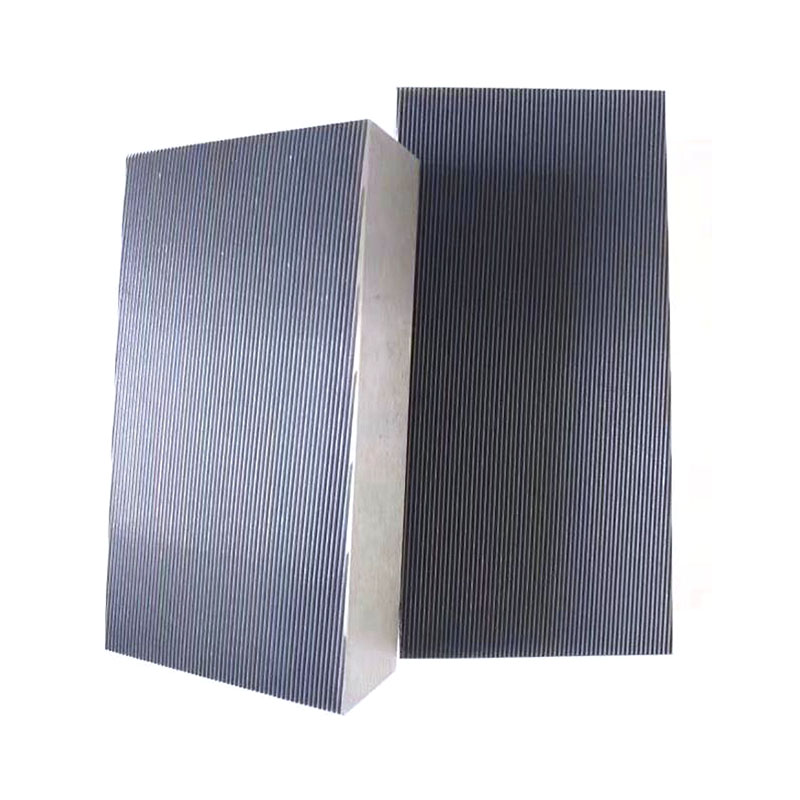

MJ Aerospace Thread are designed for specific customer applications, ranging from standard thread teeth to high precision ball screw, screw and spline applications. Thread rolling die is used for feed and through feeding process. Different processing methods are also different. There are two kinds of processing methods of rolling wheel, one is grinding, the other is rolling. The surface of the die is carburized, and the hardness of the finished rolling silk die is generally about 57-61 HRC. The hardness of the workpiece is generally below 35 HRC. If it is higher than 35 HRC, the life of ordinary thread roller will be shortened, so better material roll molds, such as DC53, HSS, etc.

Send Inquiry

1.The thread or rob processing of airline parts

2. High-precision grinding and processing method

3. The materials we used were DC53, D2, SKD 11, and Cr12Mov

4. The hardness is 58-61 HRC after heat treatment

5. Outer diameter, inner diameter, width, and keyway size can be customized

6. Heavy grinding is optional

MJ Aerospace Thread are designed for specific customer applications, ranging from standard thread teeth to high precision ball screw, screw and spline applications. Thread rolling die is used for feed and through feeding process. Different processing methods are also different.

There are two kinds of processing methods of rolling wheel, one is grinding, the other is rolling. The surface of the die is carburized, and the hardness of the finished rolling silk die is generally about 57-61 HRC. The hardness of the workpiece is generally below 35 HRC. If it is higher than 35 HRC, the life of ordinary thread roller will be shortened, so better material roll molds, such as DC53, HSS, etc.