- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

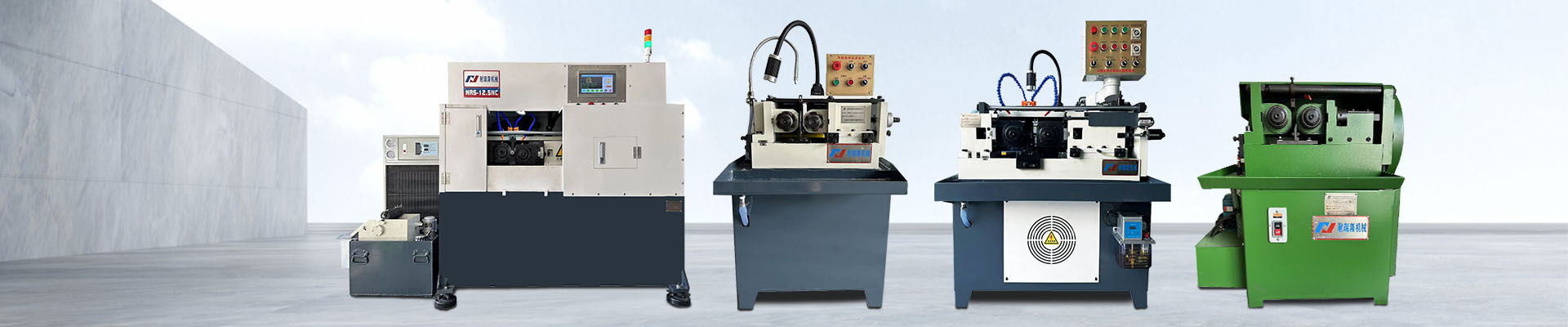

China Automatic tooth roller feeder Manufacturers, Suppliers, Factory

We always believe that one's character decides products' quality, the details decides products' quality ,with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Automatic tooth roller feeder,3T Thread roller simple automatic feeder,3T Open and Closing Roller Feeder, We are generally looking ahead to forming effective business associations with new clientele around the world.

Automatic tooth roller feeder, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part solutions. Our advantage is full category, high quality and competitive price! Based on that, our goods win a high admiration both at home and abroad.

Hot Products

Hydraulic Thru Feed Type Thread Rolling Machine

You can rest assured to buy NERES Hydraulic Thru Feed Type Thread Rolling Machine from our factory, Hydraulic indeed Thru Feed Type Thread Rolling Machine NRS-18T precision stability: the machine adopts the oil pressure system frequency conversion mechanism, PLC program control pressure and automatic impact pressure system combination, stable oil temperature in rolling.3 Roll Thread Rolling Machine For Tube

3 Roll Thread Rolling Machine For Tube can be convenient to process all kinds of tubular threads, but also suitable for all kinds of knurling, mesh, straight lines and other processing; Using equal triangle support operation, to ensure roundness, perpendicularity, easy to pass through the gauge and stop gauge; Using hydraulic (hydraulic) drive, easy operation, stable frame, durable, widely used in tubing joint, steam engine car bicycle parts and air conditioning tube evaporator, various fasteners, condenser copper pipe and other workpiece wire rolling processing.Hydraulic Bolts Thread Rolling Machines

Hydraulic Bolts Thread Rolling Machines have long life: machine structure performance balance is good, strong rigidity, stable oil pressure, and the main parts such as: universal joint, frequency converter, oil pressure system, micro dynamic switch are imported and assembled from the original equipment of the daily system, which makes the working life long, low loss of the cone, processing high precision products more stable.Spiral Point Tap

Spiral Point Tap Imported cobalt-containing high-speed steel material M35, higher hardness after heat treatment, coated with Balzers yellow titanium coating, more wear-resistant, wide processing fields, one to many, suitable for steel, iron, copper, aluminum, superalloy and other materials.Spline Rolling Dies

You can rest assured to buy NERES Spline Rolling Dies from our factory and we will offer you the best after-sale service and timely delivery. Sines and serrations are commonly used for torque transfer applications that require precise coordination with mating parts, rather than rolls that usually do not require precise fit. Half shaft, drive shaft, EV motor shaft and power output shaft are common types of splined and serrated components. Splines and serrations on the solid shaft can be rolled on Neres equipment using a feed with two molds or a single-loop roll process. In hollow shaft applications, a forced-pass rolling process with three molds can be used. The forced through-feed rolling process can also be used to produce continuous length splines and serrations on solid and hollow axes using two or three molds. The Neres spline process can achieve ANSI 5 (DIN 8) or higher accuracy tolerance.Lubricants For Thread Rolling

As the professional manufacture, we would like to provide you NERES Lubricants For Thread Rolling. Contains rich extreme pressure anti-wear agent, cooling lubricant, when the mold and metal material rolling wire, produce high temperature, contains the rolling wire oil of extreme pressure anti-wear agent, oil film will not break, play a lubrication role, reduce the adhesive wear, avoid thread surface production, reduce the defect rate.